CERTIFICATION, TESTING & SERVICES

LOGICDATA ensures the highest quality in product development. That’s why we integrate extensive testing – performed on cutting-edge measurement equipment – into our processes.

Our advanced infrastructure supports our in-house development and is available as a service for our customers: ensuring quality, safety, and simpler compliance.

Certification

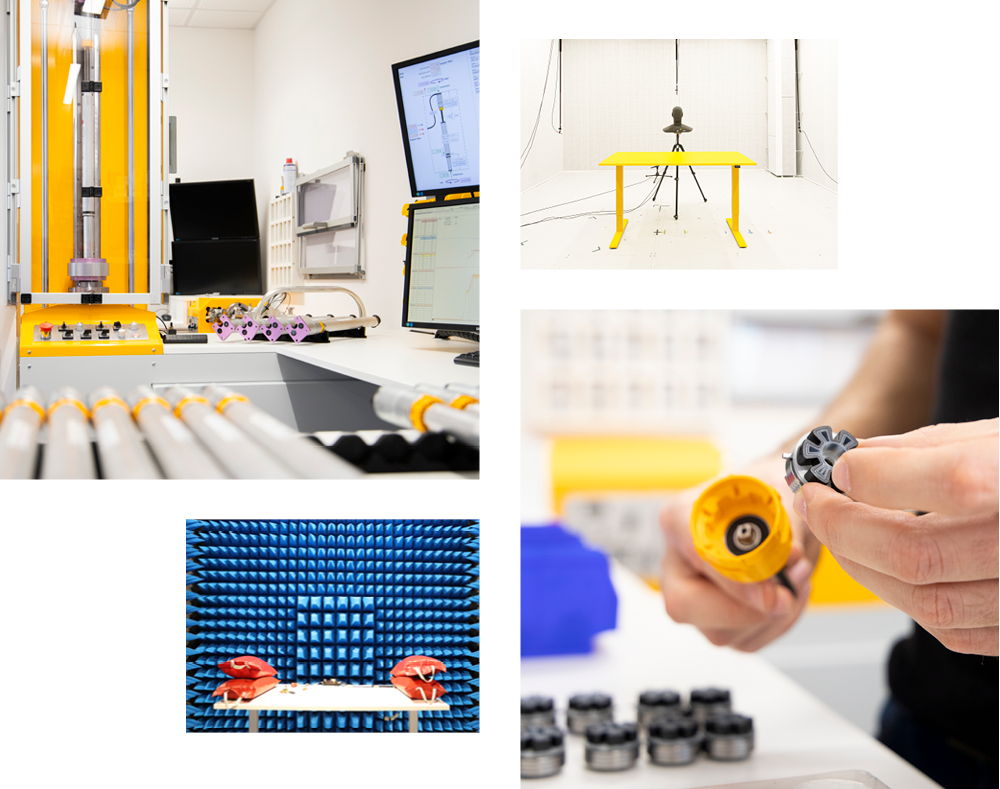

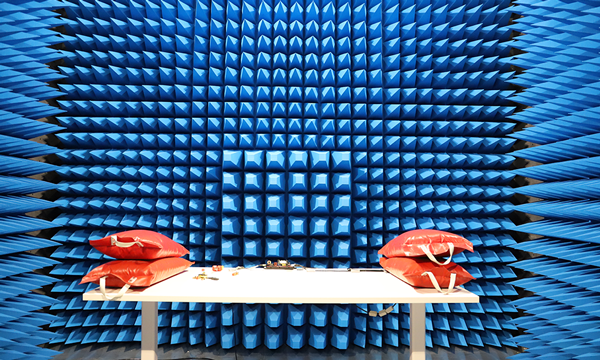

In-House EMC Expertise

We offer the full package for Electro Magnetic Compatability in product development. This includes ESD, Surge, Burst as well as Immunity tests. Our in-house EMC Chamber enables quick measurements and rapid iterations throughout development processes. As an efficient pre-testing area, we offer a significant advantage in ensuring compliance for your products.

- Conducted voltage emissions (150kHz-30MHz)

- Radiated disturbance (30MHz-1GHz/5GHz)

- Semi-anechoic chamber (8.6 × 4.9 × 5.6 m)

- 2m turntable

NVH Performance Testing

NVH (noise, vibration, and harshness) performance is a key factor in quality – and a core focus in our product development. Using our in-house acoustic testing lab and anechoic cabin, we can integrate measurement and optimization loops directly into our processes.

- Airborne sound measurement

- Structure-borne sound/vibration measurement

- In-house anechoic cabin (6.5 × 5.5 × 3.5 m)

- Microphone array for sound power measurements according to ISO3744

- Binaural recordings with HEADlab system and aurally accurate playback

- Measurement of transfer functions

- Integration of product data in NVH measurements (voltage, current, stroke and more)

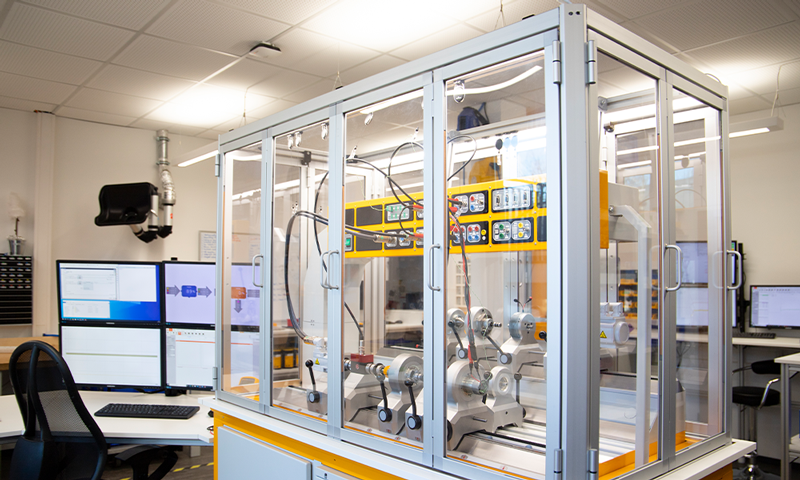

In-House Mechatronic Testing Lab

LOGICDATA’s in-depth understanding of mechatronic systems enables efficient adaption throughout development. We cover testing during initial design, feasibility testing, prototype measurement, series stability, product lifecycle management, and quality assurance.

Our in-house testing lab is a flexible, way to configure and optimize testing parameters for a wide range of requirements.

- Performance evaluation for motors, brakes, transmissions, and drive systems

- Lifetime evaluation of spindle systems (spindle, spindle nut, material, grease)

- Dynamic and static performance testing of inline actuators

- Automated test sequences with real-time value analysis during measurements