INDUSTRIALIZATION AND SERIAL PRODUCTION

LOGICDATA offers a comprehensive package that includes industrialization, serial production, and full lifecycle management.

We go beyond mechatronic development to create end-to-end solutions that meet the needs of our customers. By managing every phase of the product journey, from development through to production and lifecycle, we ensure 100% quality.

Production Line-Ready Design

LOGICDATA develops production line concepts in-house. By working closely with our suppliers, and considering production strategies from the start of product development, we ensure a manufacturing-optimized design.

Our service includes end-of-line testing for quality assurance, ensuring 100% of products meet our industry-leading standards.

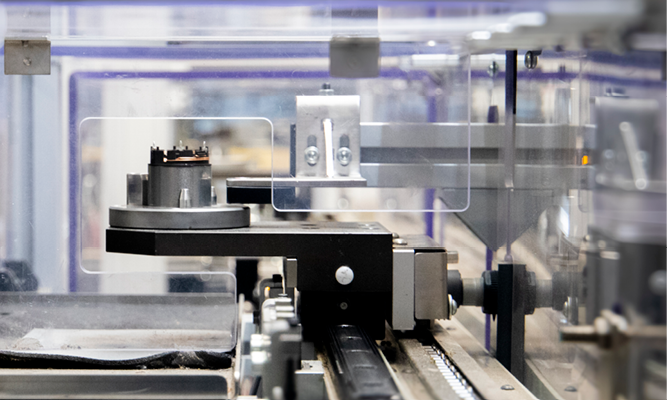

Motor Winding

At our LOGICDATA Hungary production facility, we handle brushless motor winding entirely in-house. This enables us to optimize each motor for its intended application: ensuring peak performance and reliability.

With greater control over quality, faster iteration, and precise alignment with project specifications, LOGICDATA develops and produces motors tailored to your exact needs.

Automated Assembly

LOGICDATA uses automated or semi-automated assembly lines, purpose-built for our actuator production. Motor winding processes, gearbox assembly, and spindle system assembly are fully integrated.

Our products undergo 100% end-of-line testing, verifying characteristics like NVH (noise, vibration, and harshness) for top-quality performance. This approach guarantees precision, efficiency, and consistent quality in every unit produced.

Traceability & Change Management

LOGICDATA’s approach to component sourcing ensures total traceability throughout the supply chain. With full transparency, we ensure that every part meets our rigorous quality standards.

Our robust change management system facilitates product optimization and alternative solutions, maintaining high quality while adapting to evolving requirements.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information