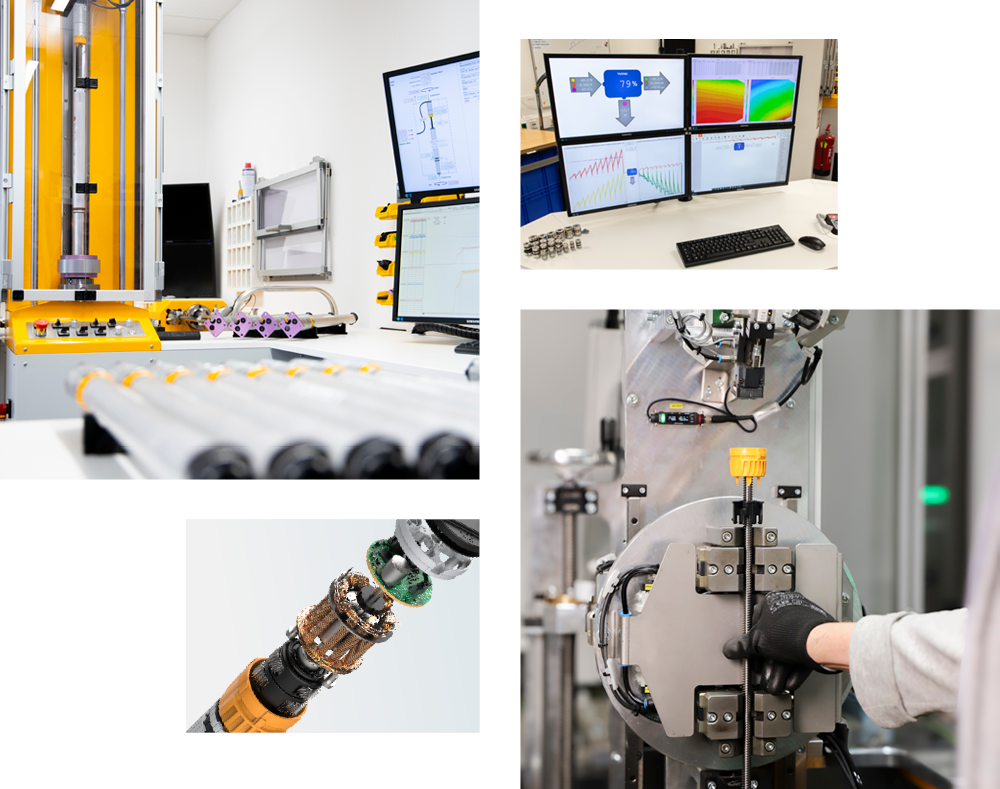

MOTOR & ACTUATOR DEVELOPMENT

LOGICDATA’s motor and actuator development is an alternative to purchasing motors with standard components. Decades’ experience enables the creation of cost-effective, system-oriented solutions – with motor topology, gearbox and spindle design.

LOGICDATA is a trusted collaboration partner for customized motor developments.

Motor Design

Proof of Concept

Motor Development

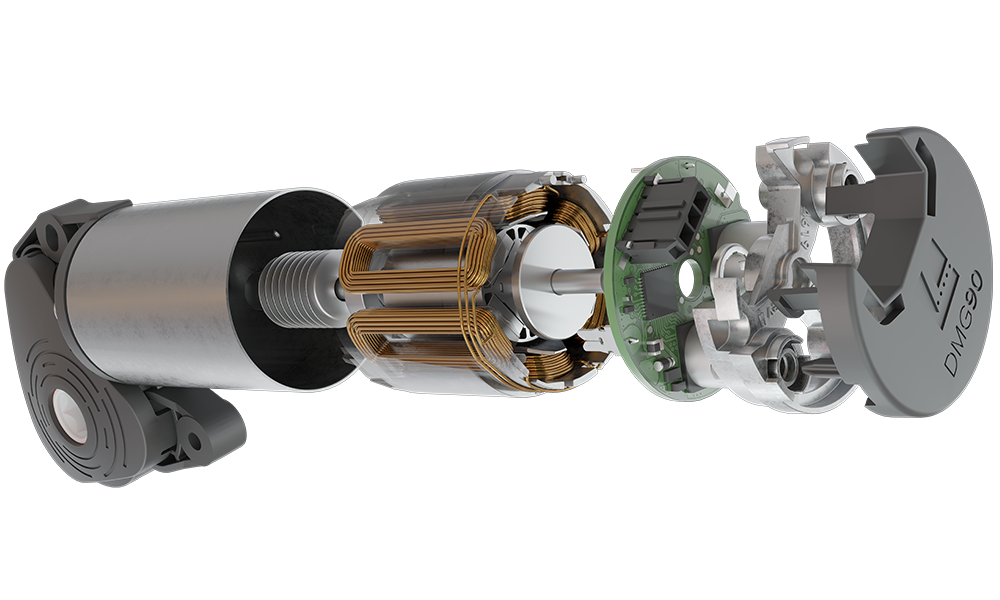

Motors define the optimal performance of a mechatronic system. To ensure an optimal price-performance ratio, we develop brushless and DC motors in-house, utilizing a combination of calculation models and prototype testing data for verification.

- Specialization on Brushless DC (PMSM) & Brushed DC motors

- In-house motor production incl. winding

- Performance range 10-500W

- Multiple motor architectures (Outer & Inner runner, coreless)

- Integrated electronics with sensorless or FOC motor control

- Integration of brake systems

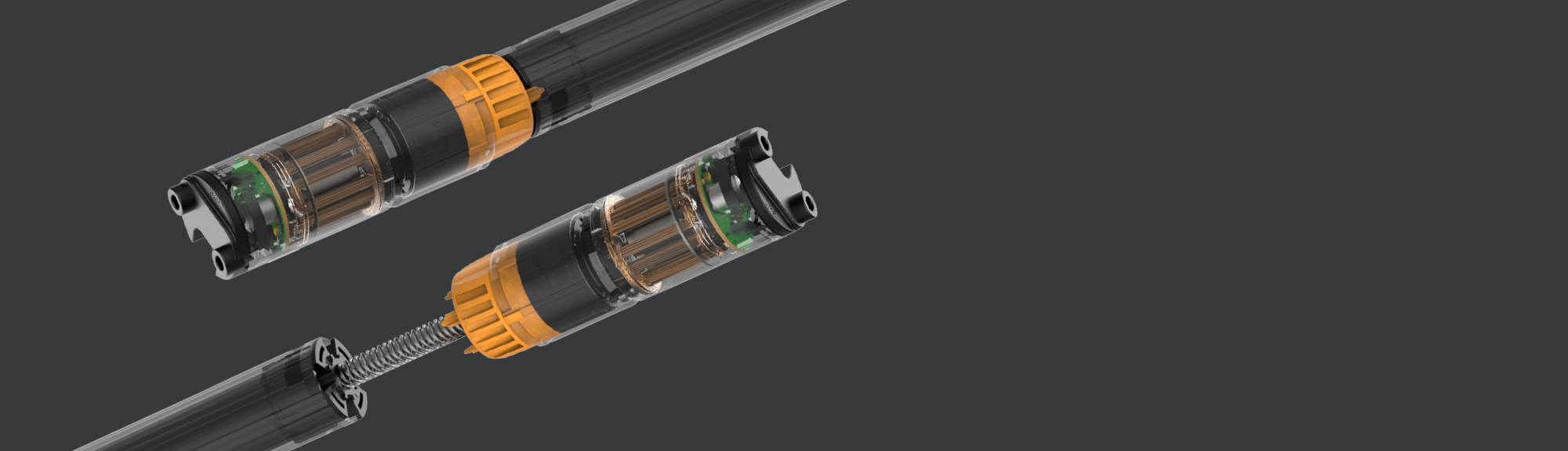

Spindle Development

Our experience in spindle system development for adjustable desks ensures efficient and cost-optimized spindles for every solution.

Performance optimization, including tribology analysis and other advanced analysis techniques, ensures reliability and efficiency.

- Design of cost-optimized telescopic systems (single & dual)

- Tribology expertise for various material & greasing combinations

- Verified computational models with own database

- Optimization of self-retention & efficiency up to 85%

- In-house spindle test stands for analysis and verification

By the Numbers: LOGICDATA Actuator Development

Gearbox Development

LOGICDATA provides in-house development of gearboxes for drive systems, with a focus on implementing plastic components for cost optimization and noise reduction.

Our expertise extends beyond development to include industrialization and quality assurance in high-volume production.

- Cost-optimized plastic components

- Planetary 1-3 stage gearbox

- Expertise in high-volume production

- Worm & Helical gearbox systems

- Integrated brake systems (active & passive)

- NVH optimization with in-house testing